The Edad de Tornillo refers to a fascinating era that marked the advent and widespread use of screws in construction, machinery, and everyday life. This period represents a significant milestone in human innovation, transforming how we approach engineering and manufacturing. Understanding its origins and applications can offer valuable insights into the evolution of technology.

The term "Edad de Tornillo" translates to "Age of the Screw" in English, symbolizing the transformative impact screws had on society. This era began with the invention of the screw and evolved into an industrial revolution, revolutionizing various fields. In this article, we will delve into the history, significance, and practical applications of screws, exploring why they remain essential today.

From ancient civilizations to modern-day industries, screws have played a crucial role in shaping the world. By examining their development and usage, we can appreciate the ingenuity behind this simple yet powerful invention. Join us as we explore the fascinating journey of the Edad de Tornillo and its enduring legacy.

Read also:Erika Rae The Inspiring Journey Of A Multifaceted Talent

Table of Contents

- The History of the Edad de Tornillo

- Innovation Behind the Screw

- Types of Screws and Their Uses

- Impact on Industry and Society

- Screw Manufacturing Process

- Modern Applications of Screws

- Sustainability and Eco-Friendly Screws

- Challenges in Screw Technology

- The Future of the Edad de Tornillo

- Conclusion

The History of the Edad de Tornillo

Origins of the Screw

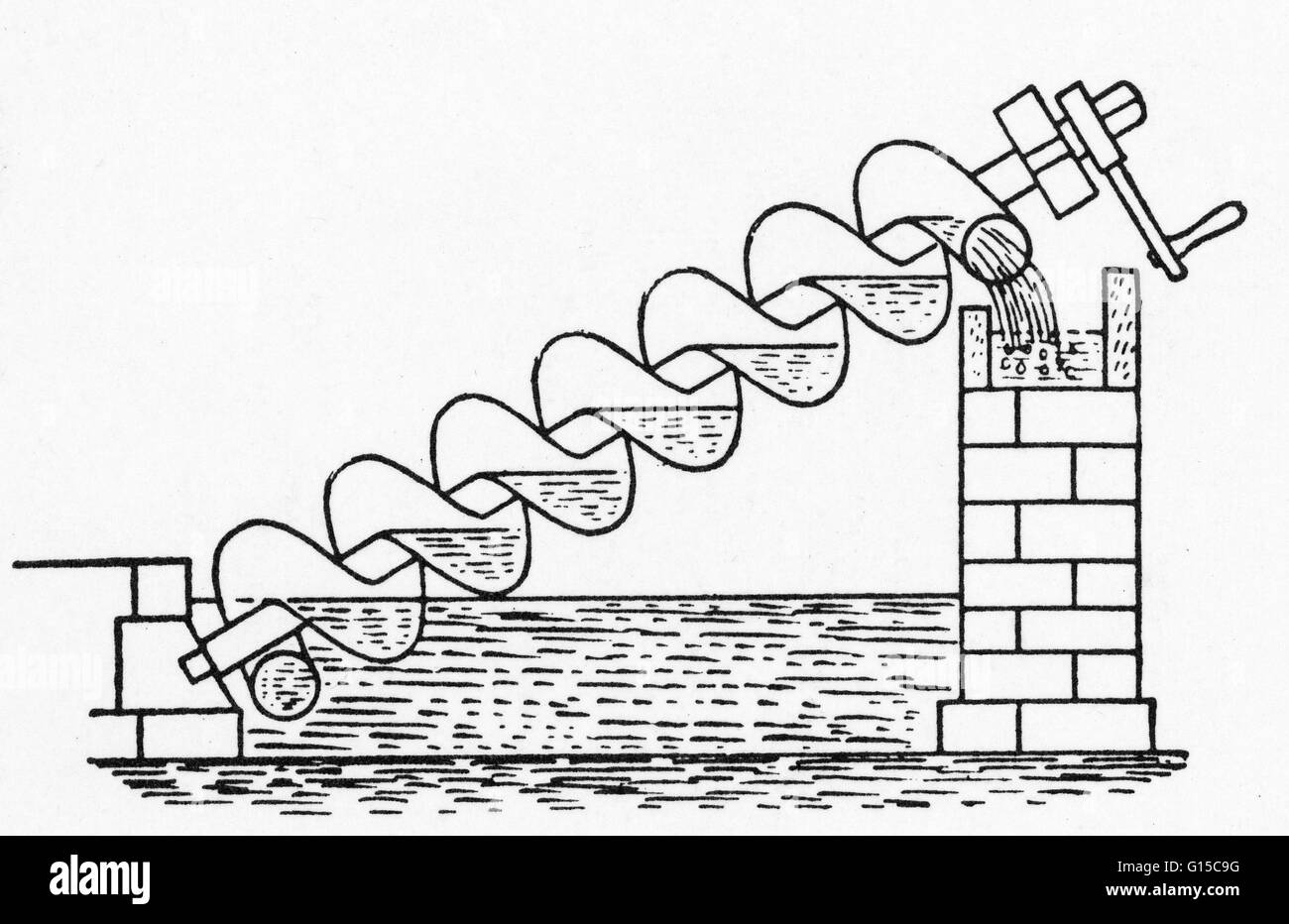

The origins of the screw date back to ancient civilizations, with evidence of early screw-like mechanisms found in Mesopotamia around 700 BCE. These early designs were primarily used for pressing olive oil and wine. Over time, the concept evolved, leading to the development of more sophisticated screws during the Roman Empire. The Edad de Tornillo truly began to take shape during the Renaissance when advancements in metallurgy allowed for the mass production of screws.

Key Developments in the 18th Century

The 18th century marked a turning point in the Edad de Tornillo. Innovators like Jesse Ramsden and Henry Maudslay introduced precision screw-cutting lathes, enabling the production of standardized screws. This innovation laid the foundation for modern engineering and manufacturing practices. The ability to produce uniform screws significantly improved the quality and reliability of machinery, contributing to the Industrial Revolution.

Innovation Behind the Screw

The screw is a deceptively simple invention that embodies complex principles of physics and engineering. Its helical shape allows it to convert rotational motion into linear motion, making it an indispensable tool in countless applications. The innovation behind the screw lies in its ability to provide both strength and adjustability, making it versatile across industries.

- Thread Design: The thread pattern of a screw determines its performance in various applications.

- Material Selection: Different materials, such as steel, brass, and titanium, offer unique properties suited to specific uses.

- Head Types: The variety of screw head designs, including flat, Phillips, and Torx, cater to different tools and torque requirements.

Types of Screws and Their Uses

Wood Screws

Wood screws are designed specifically for joining wooden components. Their coarse threads and tapered shanks provide excellent grip in wood, making them ideal for furniture assembly and carpentry projects.

Metal Screws

Metal screws, often referred to as machine screws, are used to fasten metal parts together. They feature finer threads and a smooth shank, allowing for precise alignment and secure connections in machinery and electronics.

Self-Tapping Screws

Self-tapping screws eliminate the need for pre-drilling by cutting their own threads into materials like plastic, metal, and wood. This makes them highly versatile and widely used in construction and manufacturing.

Read also:Discover The Truth About Stefanie Bloom Age A Comprehensive Guide

Impact on Industry and Society

The Edad de Tornillo has had a profound impact on both industry and society. From enabling the construction of skyscrapers to revolutionizing transportation, screws have become an integral part of modern life. Their versatility and reliability have transformed countless industries, improving efficiency and safety.

Construction Industry

In the construction industry, screws are used extensively for securing building materials, installing drywall, and assembling furniture. Their ability to provide strong, permanent connections has made them indispensable in building durable structures.

Automotive Industry

The automotive industry relies heavily on screws for assembling vehicles. From engine components to interior trim, screws ensure that every part is securely fastened, contributing to the overall safety and performance of vehicles.

Screw Manufacturing Process

The manufacturing of screws involves several stages, each requiring precision and attention to detail. The process begins with the selection of raw materials, followed by cutting, threading, and finishing. Modern technology has streamlined this process, allowing for the mass production of high-quality screws at an affordable cost.

- Material Selection: Choosing the right material based on the intended application.

- Cutting and Threading: Creating the screw's shape and thread pattern using advanced machinery.

- Finishing: Applying coatings or treatments to enhance durability and corrosion resistance.

Modern Applications of Screws

In today's world, screws continue to find new and innovative applications. From medical devices to renewable energy systems, their versatility ensures they remain relevant in cutting-edge industries. As technology advances, so too does the potential for screws to play a vital role in shaping the future.

Renewable Energy

Screws are used extensively in the construction of wind turbines and solar panels, ensuring that these critical components are securely fastened. Their ability to withstand harsh environmental conditions makes them ideal for renewable energy applications.

Medical Devices

In the medical field, screws are used in orthopedic implants, surgical instruments, and diagnostic equipment. Their precision and reliability make them essential for ensuring patient safety and successful outcomes.

Sustainability and Eco-Friendly Screws

As environmental concerns grow, there is increasing demand for sustainable and eco-friendly screws. Manufacturers are responding by developing screws made from recycled materials and incorporating biodegradable coatings. These innovations aim to reduce the environmental impact of screws while maintaining their performance and reliability.

Challenges in Screw Technology

Despite their widespread use, screws face several challenges that limit their effectiveness. Issues such as corrosion, thread stripping, and material fatigue can compromise their performance. Researchers and engineers are continuously working to address these challenges, developing new materials and designs to improve screw technology.

The Future of the Edad de Tornillo

The future of the Edad de Tornillo looks promising, with ongoing advancements in materials science and manufacturing technology. As industries continue to evolve, so too will the role of screws in shaping the world. From smart screws with embedded sensors to self-healing materials, the possibilities are endless.

Conclusion

The Edad de Tornillo represents a pivotal chapter in human history, highlighting the transformative power of innovation. From its humble beginnings in ancient civilizations to its current role in cutting-edge industries, the screw has proven to be an indispensable tool. By understanding its history, applications, and future potential, we can appreciate the profound impact it has had on society.

We invite you to share your thoughts and experiences with screws in the comments below. Whether you're a professional engineer or a DIY enthusiast, your insights can help others learn and grow. For more fascinating articles on technology and innovation, be sure to explore our website further.

Data Sources: - "The History of the Screw" by Smithsonian Magazine - "Screw Manufacturing Processes" by ASTM International - "Sustainability in Fastener Production" by ISO Standards